-

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

+86 186-3793-7107

+86 186-3793-7107

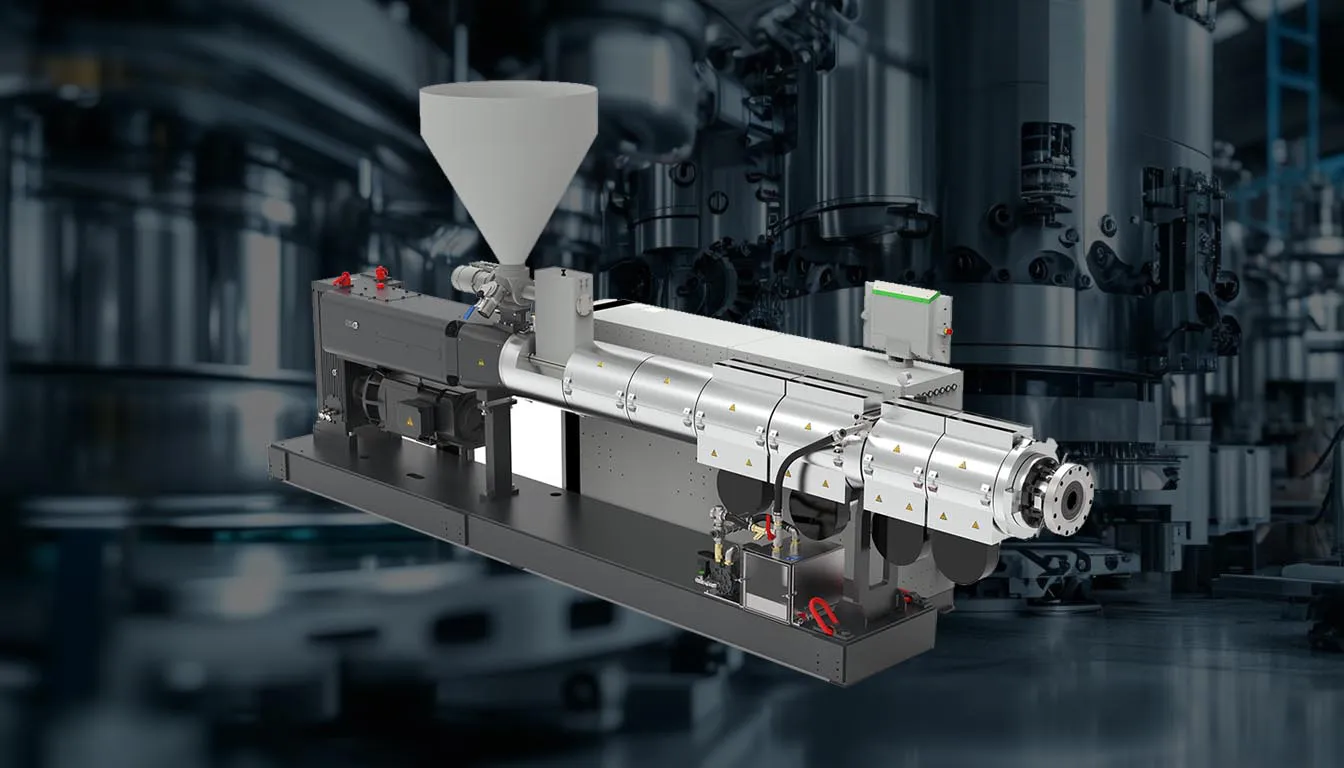

Twin Screw Extruder

Twin screw extruders often use tandem thrust cylindrical roller bearings as the main shaft bearings. This type of bearing has the characteristics of small radial cross-sectional size, compact structure, high axial load capacity, uniform load on each row of rollers, wear resistance, low vibration noise, and long service life, which is very suitable for the needs of parallel twin-screw extruders. Configuration method: Users can choose the appropriate number of bearing rows based on the screw center distance, space, and load size, such as two, three, four, five, six, seven, or eight series bearings. In addition, there are design considerations such as preload, radial guidance, elimination of tilt, fit tolerance, and bearing lubrication to ensure the correct operation and long life of the bearings.

Contact Us

Type selection: Twin-screw extruders often use tandem thrust cylindrical roller bearings as main shaft bearings. This type of bearing has the characteristics of small radial cross-section size, compact structure, large axial load capacity, uniform load on each row of rollers, wear resistance, low vibration and noise, and long life, which is very suitable for the needs of parallel twin-screw extruders.

Configuration method: Users can choose the appropriate number of bearing rows according to the screw center distance, space and load size, such as two, three, four, five, six, seven or eight rows of tandem bearings. In addition, there are design considerations such as preload, radial guidance, elimination of tilt, matching tolerances and bearing lubrication to ensure the correct operation and long life of the bearings.

High load capacity

The high load capacity of the bearing enables the twin-screw extruder to handle high-torque and high-load conditions, ensuring the stability and reliability of the extrusion process.

Long life

Bearings made of high-quality materials and advanced manufacturing processes have a long service life, reducing replacement frequency and maintenance costs.

Low vibration and noise

The precision design and high-quality materials of the bearings help reduce the vibration and noise levels of the extruder and improve the comfort of the production environment.

High adaptability

The diversity and configurability of the bearings enable the twin-screw extruder to adapt to the needs of different materials, formulas and processes, achieving the goal of one machine for multiple uses and one machine for multiple functions.

Improve production efficiency

High-quality bearings can ensure the continuous and stable operation of the extruder, reduce downtime, and thus improve production efficiency.

Reduce maintenance costs

The easy maintenance and long life of the bearings help reduce the overall maintenance cost of the twin-screw extruder.

The application of bearings in twin-screw extruders not only ensures the stable operation and efficient production of the extruder, but also improves the load-bearing capacity, life, adaptability and maintainability of the equipment. Therefore, when selecting and using bearings, it is necessary to fully consider the specific application requirements and working conditions to ensure the best performance and economic benefits of the extruder.+86 18637937107

Manager Tan

Phone: +86-186-3793-7107

Mails: sales@kblzc.com

Address: No.1, North Side of Wulonggou Bridge, Xihuan Road and Qiangou Village Road, Luoyang City, Henan Province

QR code