-

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

+86 186-3793-7107

+86 186-3793-7107

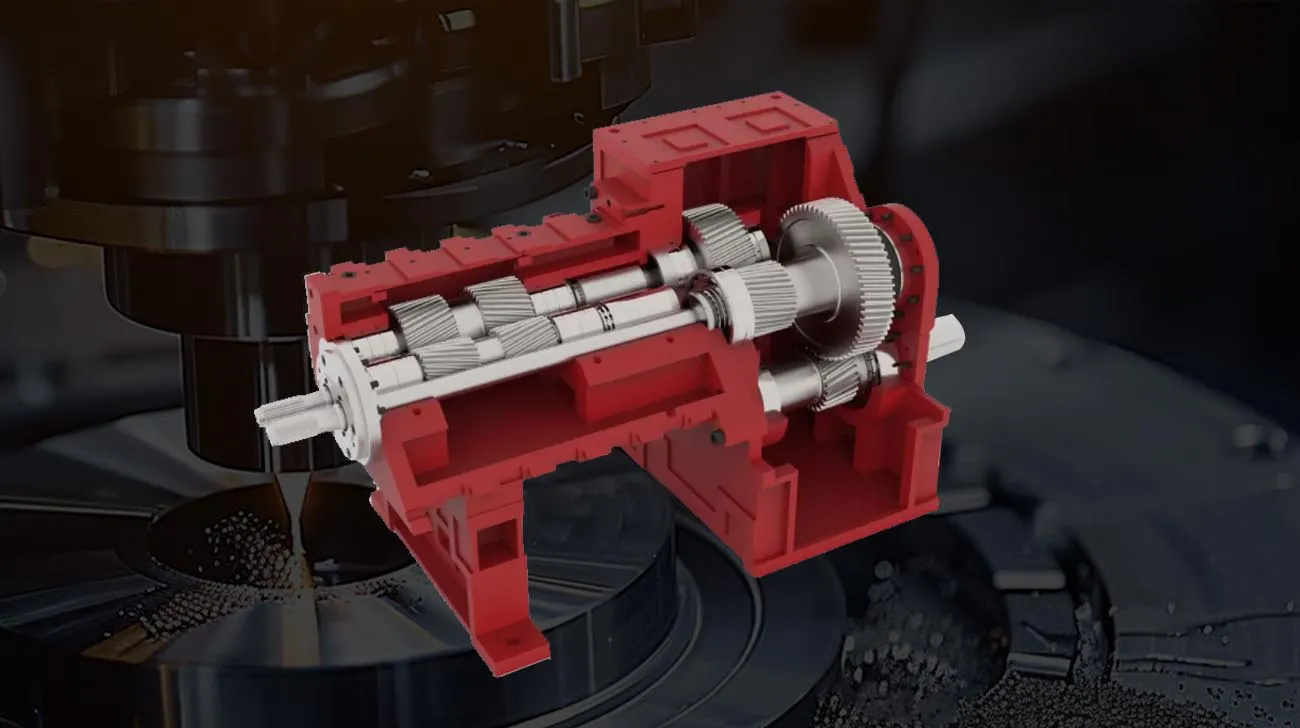

Twin Screw Extruder Gearbox

Tandem thrust cylindrical roller bearings have the characteristics of small radial section size, compact structure, large axial load capacity, uniform load on each row of rollers, wear resistance, low vibration and noise, and long life. It is an ideal screw spindle bearing for the gearbox of a parallel twin-screw extruder, and can meet the operating requirements of the equipment under high load and high speed.

Contact Us

Tandem thrust cylindrical roller bearings are widely used in gearboxes of parallel twin-screw extruders in the rubber and plastics industry due to their superior axial load-bearing capacity, compact structure and long service life. In this application, it can not only effectively support the axial movement of the screw, but also withstand various forces and torques generated by the screw during rotation, ensuring the stable operation of the extruder.

Small radial section size and compact structure:

The radial section of the tandem thrust cylindrical roller bearing is relatively small, which allows it to be flexibly installed in gearboxes with limited space and adapt to different installation environments and requirements.

Large axial load capacity:

The bearing has super axial load capacity and can easily cope with the huge axial force generated by the twin-screw extruder at high speed, ensuring the stability and precision of the screw.

Even load on each row of rollers:

The design of tandem thrust cylindrical roller bearings enables each row of rollers to bear the load evenly, which not only improves the bearing's load-bearing capacity, but also extends the bearing's service life.

Wear-resistant, low vibration and noise:

The bearings are made of wear-resistant materials, have good wear resistance, and can reduce wear and heat caused by friction. At the same time, its structural design also helps to reduce vibration and noise and improve the smooth operation of the equipment.

Long-term working life:

Due to the combined effect of the above advantages, tandem thrust cylindrical roller bearings have a long working life in the twin-screw extruder gearbox, reducing the frequency of equipment maintenance and bearing replacement, and reducing operating costs.

Application of preload device:

In some high-end twin-screw extruders, a reduction gearbox with a tandem thrust bearing preload device is also used. This device keeps the bearing in a good radial centering state by preloading, further improving the bearing's load-bearing capacity and stability.

Tandem thrust cylindrical roller bearings are widely used in twin-screw extruder gearboxes, and their unique structural design and superior performance characteristics make them an ideal choice in this field. With the continuous advancement of technology and continuous improvement of processes, it is believed that the application of tandem thrust cylindrical roller bearings in twin-screw extruders will be more extensive and in-depth.

+86 18637937107

Manager Tan

Phone: +86-186-3793-7107

Mails: sales@kblzc.com

Address: No.1, North Side of Wulonggou Bridge, Xihuan Road and Qiangou Village Road, Luoyang City, Henan Province

QR code