-

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

+86 186-3793-7107

+86 186-3793-7107

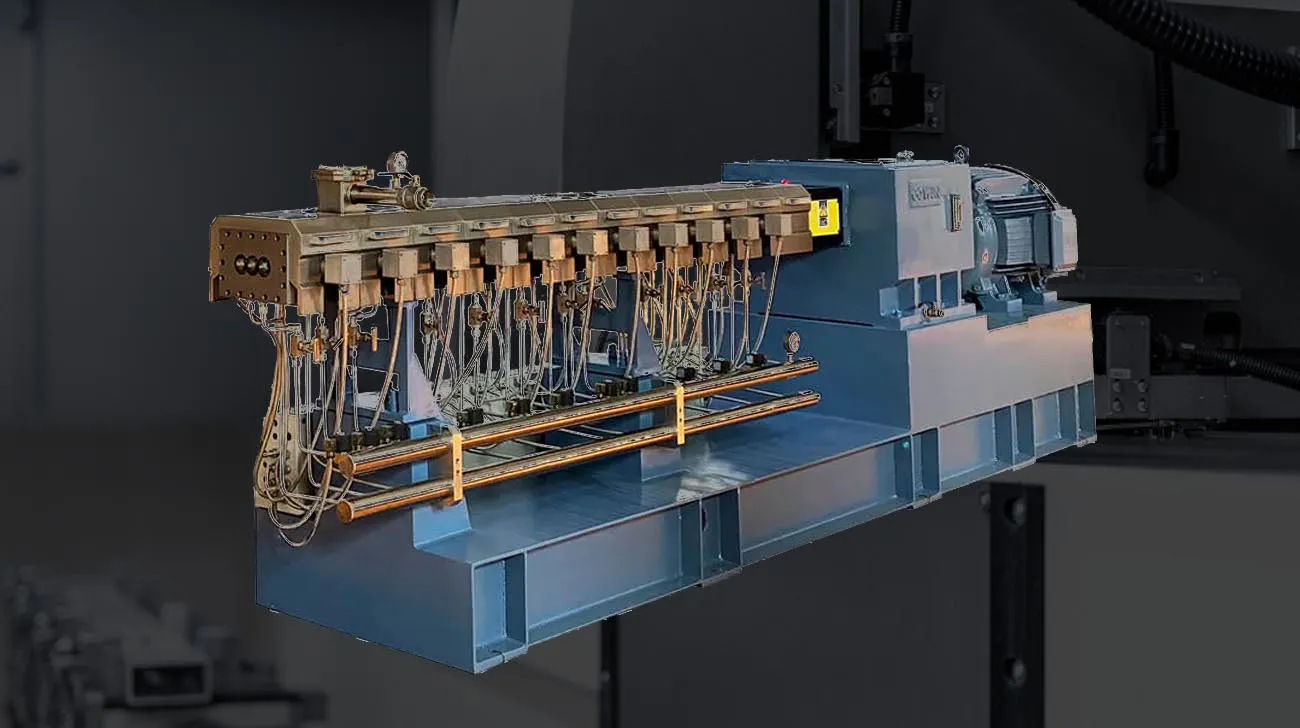

Three Screw Extruder

塑料颗粒挤出机轴承在三螺杆挤出机中得到了广泛应用。塑料颗粒挤出机轴承具有承载能力强、适应性强、性能稳定可靠、易于安装和维护以及耐高温高压等特点。这些特点使得轴承在塑料颗粒挤出机在三根螺杆的支撑部件,确保螺杆在高速、高负荷的运转过程中能够保持稳定的旋转。

Contact Us

Three-screw extruders usually use plastic pellet extruder bearings, which have strong bearing capacity, small radial cross-sectional size, large axial load capacity, uniform roller load, low wear resistance, low vibration and noise, and long life. These characteristics are crucial for the normal operation of the extruder and the processing quality of plastic pellets.

Key components in the transmission system: It also participates in the transmission system, responsible for transmitting power and torque from the motor, ensuring that the three screws can operate in coordination at a predetermined speed and direction. This synergy helps to achieve more efficient material mixing and extrusion effects.

Improve mixing effect

Three-screw extruders usually have three meshing points, which is equivalent to multiple pairs of twin screws acting at the same time, which can subject the material to stronger shear, extrusion, kneading and grinding, thereby better homogenizing and dispersing the material and improving the mixing and kneading effect.

Increase production

Due to its unique structure and high shear zone, it can achieve higher production than twin-screw extruders of the same specification.

Good exhaust performance

The material is almost sucked into the mixing area at the center of the screw, which is equivalent to a melt pump. There is almost no material accumulation at the exhaust port, no material overflow, no blockage, etc., and it can achieve a very high vacuum degree, thereby improving product quality.

Adapt to high filling

A high filling ratio can be achieved, such as the carbon black content can reach 55% when producing carbon black masterbatch, the magnesium hydroxide content of low-smoke halogen-free flame-retardant cable material can reach 90%, and the calcium carbonate addition amount of PP or PE masterbatch can reach more than 85%, and the effect is good.

Reduce energy consumption

The aspect ratio is short, the screw length is relatively short, the main engine power, heater power and other powers are reduced, which can significantly reduce energy consumption; and its positive displacement conveying capacity is strong, and the space for free flow of materials in the barrel is increased, which is conducive to reducing the screw torque, thereby further reducing energy consumption. In addition, the three-screw has a short aspect ratio, a small model, and a small space occupation, and the loss of water, electricity and other energy is smaller than that of general twin-screw machines.

Guaranteed stability

It has the characteristics of small radial section size, compact structure, large axial load capacity, uniform load on each row of rollers, low wear resistance, low vibration noise, and long life. It can bear heavy loads in a limited space and firmly support it in the axial direction for long-term use with low friction power.

+86 18637937107

Manager Tan

Phone: +86-186-3793-7107

Mails: sales@kblzc.com

Address: No.1, North Side of Wulonggou Bridge, Xihuan Road and Qiangou Village Road, Luoyang City, Henan Province

QR code