-

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

Products CenterLuoyang Kebelong Bearing Co., Ltd. specializes in the production and design of tandem thrust cylindrical roller bearings, cross roller bearings, and non-standard customized bearings, with rich design experience.

+86 186-3793-7107

+86 186-3793-7107

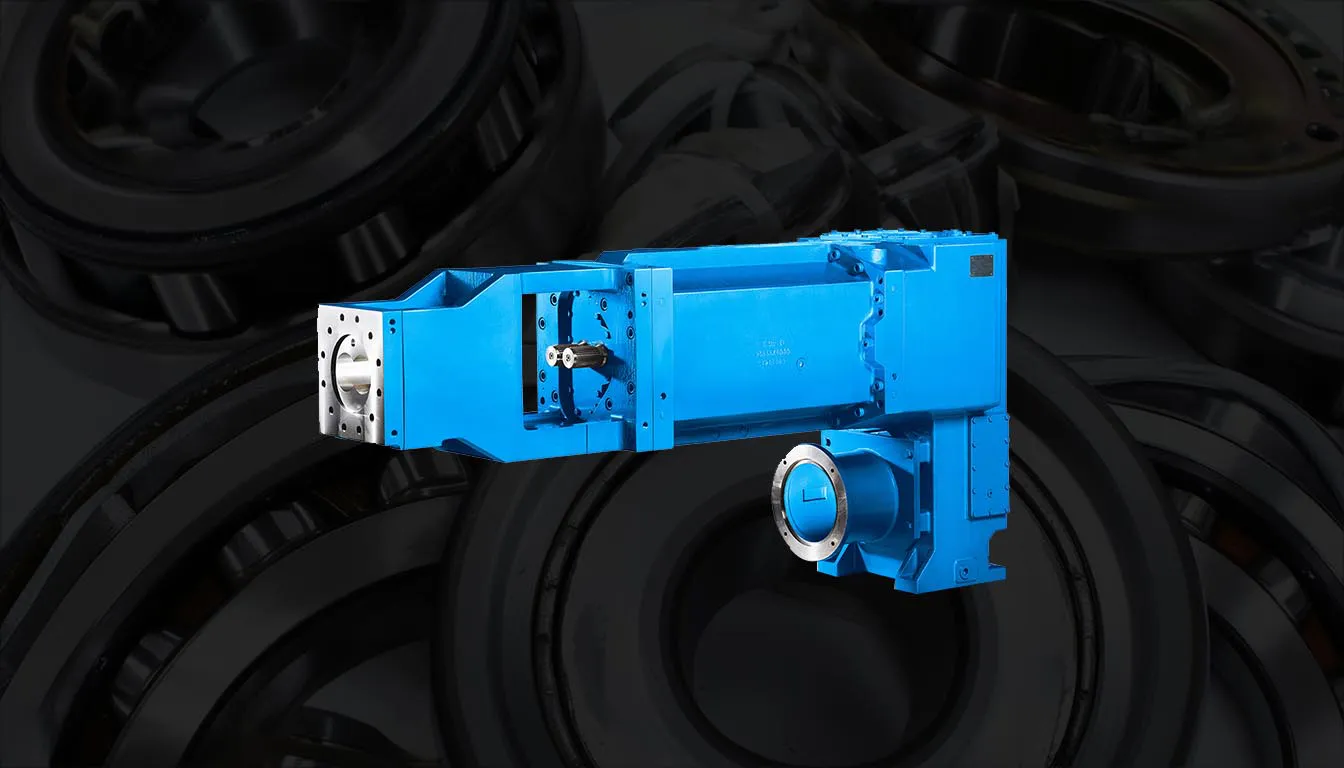

Extruder Gearbox

The plastic pellet extruder gearbox is an important part of the extruder, responsible for converting the high-speed rotation of the motor into the low-speed and high-torque rotation of the extruder screw to realize the extrusion process of plastic pellets. The application of plastic pellet extruder bearings in the extruder gearbox has many advantages, which not only improve the performance and reliability of the extruder, but also reduce the operating costs and maintenance difficulties of the enterprise.

Contact Us

The plastic pellet extruder gearbox is an important part of the extruder, responsible for converting the high-speed rotation of the motor into the low-speed and high-torque rotation of the extruder screw to realize the extrusion process of plastic pellets. In this process, the bearing, as a key component in the gearbox, undertakes the important tasks of support and rotation. Specifically, the plastic pellet extruder bearing is usually installed on the input shaft, output shaft and transmission shaft of the gearbox, transmitting torque and bearing load by rolling or sliding to ensure the normal operation of the gearbox.

High load-bearing capacity

The plastic pellet extruder needs to withstand large loads and impacts during operation, and high-quality bearings have excellent load-bearing capacity, which can ensure that the gearbox can still operate stably under harsh working conditions.

Long life

Plastic pellet extruder bearings are usually made of high-quality materials, and are precision machined and heat-treated, with high hardness and wear resistance. This design enables the bearing to withstand long-term high-speed operation and frequent start-stop, thereby extending the service life of the bearing and reducing maintenance costs.

Low noise

The bearing generates less noise during operation, which helps to improve the working environment and reduce noise pollution. This is of great significance to improving production efficiency and employee satisfaction.

Self-lubrication

Some plastic pellet extruder bearings adopt a self-lubricating design, which can automatically replenish lubricants during operation to reduce friction and wear. This design not only reduces the difficulty of bearing maintenance, but also improves the reliability and stability of bearings.

Corrosion resistance

During the plastic pellet extrusion process, some corrosive substances may be produced. High-quality bearings usually have excellent corrosion resistance, which can resist the erosion of these substances and ensure the long-term stable operation of the gearbox.

Cost-effectiveness

Although the initial investment of high-quality bearings may be higher, their long life, low maintenance cost and high efficiency make the overall cost-effectiveness higher. In the long run, the use of high-quality bearings can reduce the operating costs of enterprises and improve production efficiency.+86 18637937107

Manager Tan

Phone: +86-186-3793-7107

Mails: sales@kblzc.com

Address: No.1, North Side of Wulonggou Bridge, Xihuan Road and Qiangou Village Road, Luoyang City, Henan Province

QR code